The line is intended for the production of corn sticks in a fully automated mode. Performance of 100-120 kg / h.

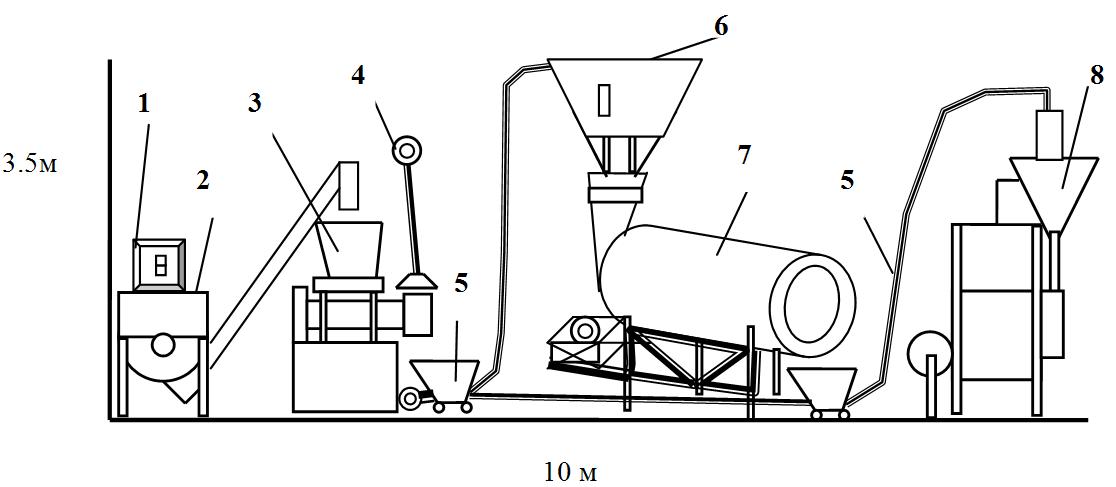

The line consists of:

1. The apparatus for preparing and pulverizing of components

2. Air-conditioning mixer with supply of cereals into the feed hopper of the extruder

3. Extruder EKP-250

4. Exhausting

5. Pneumatic conveyors - 2 pieces

6. Storage bin

7. Tunnel grinder

8. Packaging machines UAFU

9. Outflow conveyor with table

How it works:

The raw (corn stick) is moisturized in mixer before extruding. The apparatus for preparing and pulverizing of components, in which it is prepared the solvent for the raw moisturizing, is installed above the mixer. Then, the raw is fed into the feed hopper of the extruder by the screw conveyor.

At the exit of the extruder we have the semi-fabricate – the corn stick. This semi-fabricate is automatically fed into the storage bin with pneumatic conveyor. The stick moves by means of vibrating batcher from the storage bin into the tunnel grinder where the product is sprayed automatically with oil and dry flavor additives are put in it. After the stick exits from the grinder we get the finished product.

The product comes into the hopper of pneumatic conveyor and fed into the hopper of filling machine. At the exit from the filling machine we have the finished product covered with polymeric film – corn stick with the flavor additive. The packs are transferred from the filling machine to the outflowing conveyor which lifts the packs on the filling table where they are filled in the transporting containers.

technical characteristics;

Occupied area of 35 sq.m.

Attendants, 2-3 persons.

Performance of 50-120 kg / hour, depending on the diameter of 12-23mm sticks.

Photo: