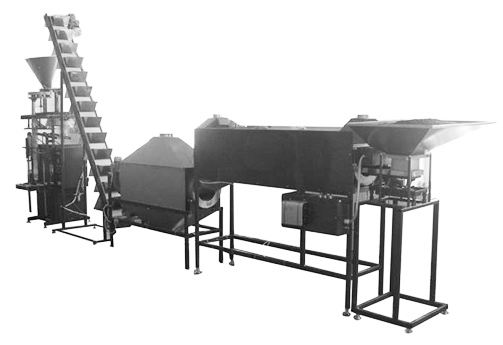

Line is a set of equipment for fully automated production process and packaging of fried seeds.

Automatic line consists of the following components (in the order of technology cycle of roasting and packing):

| Position | Component | Variants of execution |

| 1 | Roasting | Electric continuous roasting furnace |

| 2 | Cooling |

PassingCooler-Cleanerpass |

| 3 | Feeding | Bucket loading conveyor loading bucket VZ-1 |

| 4 | Filling and packaging | Pneumatic packaging machine with volumetric doser ** Pneumatic packaging machine with weight doser** Mechanical packaging machine with volumetric doser Mechanical packaging machine with weight doser Pneumatic mechanical packaging machine with volumetric doser Pneumatic mechanical packaging machine with weight doser |

** using pneumatic automate in line structure, it is additionally required the compressor that provides operation of pneumatic devices (sold separately).

To increase the line productivity by 2 times, you can set two roasting furnaces

Technical specifications of the line:

| Power supply | |

| Supply voltage, V | 380 |

| Supply current frequency, Hz | 50 |

| Electric power consumption (maximum), kW / h | 22 |

| Dimensions and weight | |

| Length (max) mm | 9 200 |

| Width (max) mm | 2 000 |

| Height (max) mm | 3 700 |

| Weight (max), kg | 600 |

| Work features | |

| Raw material hopper capacity, l | 60 |

| Recommended raw material moisture (maximum),% | 8 |

| Performance (max), kg / h: * | 70 |

* line performance depends on the kind of packed product, it flowability, density, moisture, dose size and packaging material properties. I is given to seeds (sunflower seeds) with the moisture of 8%

Description of the line operation:

The line operates automatically and the operator only needs to set the parameters of operation, to ensure the supply of raw materials and to remove the finished products. Raw material is cleaned and calibrated seed, which is fed into the hopper of electric furnace.

Hopper of the furnace can be filled by hand (from bags) as well as it is possible to apply the conveyor which will be supplied from any storage device. Further, the raw material passes through all elements in line, where it is fried, cooled and packed.

After raw materials have passed through all elements of the line, the received finished product (roasted seeds) packed in containers for selling - a polymer film. After packaging, the operator must ensure picking up the packages. Picking up the packages can be done manually or by setting discharging conveyor, which will supply packages to reception table for packing in shipping containers.