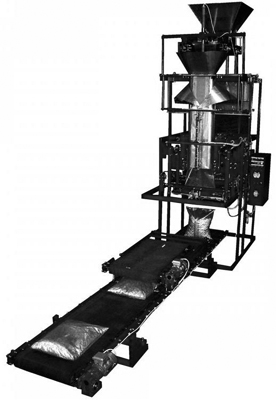

Filling and packaging machine is equipped with a weight batcher and is designed for filling in bags by high doses of non-dusting product having a good flowability, such as feed, fuel granules, washing powder, sand, pellets, sugar, grain, salt, soil, pebbles, gravel, fillers for animals and so on.

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 2,5 |

| Power of pneumatic drives | |

| Air pressure in line (average), atm. | 6 |

| Airconsumptionattheaveragepressure, l./min. | 100 |

| Overall dimensions and weight | |

| Length (max), mm | 5500 |

| width (max), mm | 1500 |

| height (max), mm | 4500 |

| weight (max), kg | 650 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-150 |

| Width of the roll (max), mm | 1250 |

| External diameter of the roll (max), mm | 500 |

| Working characteristics | |

| Volume for the hopper for packaged product, l | 140 |

| Nominal tube volume, sm3 * | 5000-50000 |

| Dosage error (allowable), % | 2 |

| Dosingspeed (max), doses/min: * | 10 |

| Welding (soldering), packingtime (includingcooling), sec. | 3-5 |

| Heating of welding unit (welding method) | Continuous |

| Length of packing (max), mm | 900 |

| Packing width (max), mm | 500 |

| Adjustable parameters | |

| Dose weight (range), g | 5000-50000 |

| Heatingtemperatureoftheweldingunit (range), g. Celsius | 80-200 |

| Weldingcycletime (welding unit in compressed state), sec. | 0-5 |

| Contacttimeoftheweldingelementwithpackingfilm, sec. | 0-5 |

* There is metal pipe under the tube, passing through which the product fills in the package. The product batching is carried out by filling the internal capacity of the tube to the capacity sensor position. The nominal tube volume (to the top level of capacity sensor) determines the maximal dose, issued into the package.

** dosing speed of the packing machine depends on the type of packaged product, its flowability, density, moisture content, dose size and properties of packaging material.

*** Changing of the dosage sizes is carried out by changing capacity sensor position inside the tube (the height of the position defines the dosage size).

To insure the functionality of pneumatic drives of this packing and filling equipment it is necessary to have compressor (is supplied separately).