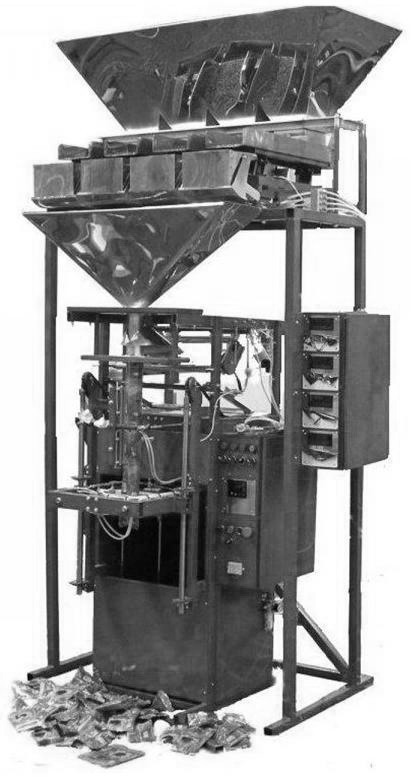

Filling and packaging machine is used for continuous process of packaging by weight dosing method of different flowability, (hard-flowable) non-dust products and packaging into the polymer films.

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 1 |

| Power of pneumatic drives | |

| Airpressureinline (average), atm. | 6 |

| Airconsumptionataveragepressure, l./min. | 100 |

| Overalldimensionsandweight | |

| Length (max), mm | 2000 |

| width (max), mm | 1500 |

| height (max), mm | 3000 |

| weight (max), kg | 350 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 380 |

| External diameter of the roll (max), mm | 300 |

| Working characteristics | |

| Volume of the hopper for raw material, l | - |

| (бункер с 1 горловиной) | 60 |

| (бункер с 2 горловинами) | 120 |

| (бункер с 3 горловинами) | 180 |

| (бункер с 4 горловинами) | 240 |

| Dosing limits (nominal dose weight), g | 20-2000 |

| Dosage error (allowable), % | 2 |

| Dosingspeed (max), doses/min: * | - |

| (batcher with 1 «stream» **) | 10 |

| (batcher with 2 «streams» **) | 20 |

| (batcher with 3 «streams» **) | 30 |

| (batcher with 4 «streams» **) | 40 |

| Welding (soldering), packingtime (includingcooling), sec. | 1-2 |

| Heating of welding unit (welding method) | Continuous |

| Length of packing (max), mm | 300 |

| Packing width (max), mm | 200 |

| Adjustable parameters | |

| Weight of dose (range), g | 20-2000 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* Packing equipment performance depends on the type of packaged product, its flowability, density, moisture content, dose size and properties of packaging material.

** the “stream” means units and devices insuring forming of separate stream of the packed product from the batcher-hopper, its division by doses and issuing these doses in the certain subsequence. The “stream” consists of: the hopper spout with hopper, vibrating chute disposed below a spout, the weighing beaker in which the vibrating chute feed the product, and a controller unit controlling the operation of the vibrating chute and weighing beaker.

To insure the functionality of pneumatic drives of this packing and filling equipment it is necessary to have compressor (is supplied separately).