Line for production of baby food for children from 6 months age: quick-cooking cereals (dairy-free, dairy, with natural dried fruit and vegetables) from a variety of cereals.

The company “Waiz” for 17 years produces itself 6 types of baby food of TM “Niam-Niam” and 26 species of quick-cooling cereals TM “Hvilinka”.

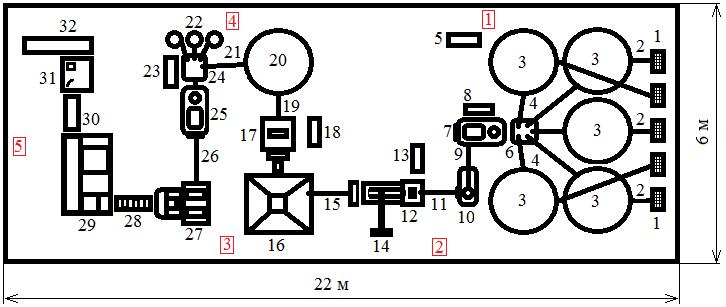

DESCRIPTION OF THE LINE FOR PRODUCTION BABY FOOD FOR CHILDREN FROM 6 MONTHS AGE

The basic raw material for product is high-quality cereal flour, specially made by all standards and safety parameters for production of baby food. Flour is delivered to the plant in four-bags of 30 kg, and in which it is stored at the plant under the certain conditions.

Before launching the line, the flour is via the bag distribution devices (1) and loading screw conveyors (2) is loaded into the technological hoppers (3). There are 5 of such bins - for different types of flour. The bins are equipped with level sensor system and prevent bridging. According to a predetermined process recipe the flour (each type separately) by dosing screws (4) is fed into the weighing terminal (6).

Dosing error is less than 1%. Bin downloading management is made with the control panel 5, batching complex with control panel 8, which are located directly next to the equipment. Upon reaching the desired weight parameters of all components according to the formulation, the raw material is discharged into the mixer (7) to ensure the uniformity of the whole mass. Mixing cycle makes 2-5 minutes (depending on the set parameters). Then, the raw material with the screw conveyor (9) is loaded into the sifter (10), which is equipped with a magnetic separator.

The next stage - extrusion. By means of the screw conveyor (11) the mixture of raw materials is loaded into the hopper of the extruder (12), where it is batched to the feed housing of the extruder. Using a dosing pump that supplies water to the feed housing of the extruder the raw is moistened. Due to the intensive thermal-mechanical treatment the raw being time in the extruder housing (5-7 seconds) gets the necessary sanitization, and during processes under the influence of considerable shear rates, high speeds and pressure, mechanical energy transfers into the heat energy, leading to various deep changes in quality indicators of processed raw, such as protein denaturation, starch gelatinization and gelation, as well as other useful for better assimilation by the child biochemical changes. Cutting of the product is made directly from the die using cutter device. All work of the extruder is controlled from the remote control unit (13). The extractor (14) is installed over the extruder to remove the vapor.

The ready semi-finished product is delivered to the collecting hopper (16) with the pneumatic conveyor (15). Then, the semi-finished product gets into the crusher (16) for crushing in porridge. Then the crushed mass with a screw conveyor (19) is loaded into the technological storage bin (20). These processes are controlled by the control unit (18).

The porridge is loaded from the storage hopper in the weighing terminal (24) with the screw conveyor (21). Depending on the technological recipe , .), additives in predetermined amounts is loaded in the weight terminal from the containers for dry additive (22) by the screw conveyors (each type separately: vitamins, dried fruits, etc) for the further mixing with a porridge in mixer ( 25). Upon reaching the end of the cycle of mixing (2-5 minutes) the product with the screw conveyor (26) is supplied to the feed hopper of the packing machine. The process of batching and mixing of the components is controlled by the control unit (23).

The product in a given weight range is filled and packed in a bag in the packaging machines (27). Then the packaged product using the outflowing conveyor (28) is supplied to the automated packer in a cartoon (29) for packing in a cartoon containers and application the date of production and other information on it. At the exit of cartoon packager the product using the horizontal conveyor (30) falls on the packaging table (31) for laying in the group transport container. The packing is made by the packers. The product packed in a shipping container, with the horizontal conveyor (32) is supplied to the warehouse for storage finished products.

Connection of communications to production shop (connection points):

1 - Power supply 3ph, 380V 50 Hz; total consumption of 7.5 kW / h. Compressed air; consumption by vibrating fans is 1000 l/ min. Water for washing.

2 - Power supply 3p, 380V 50 Hz; total consumption of 145 kW / h.

Water for washing; Cooling the extruder of up to 150 l / h.

Compressed air; consumption by pneumatic conveyor 1000 l / min.

3 - Power supply 3ph, 380 V 50 Hz; Total consumption of 7 kW / h. Water for washing.

4 - Power supply 3ph, 380V 50 Hz; total consumption of 4 kW / h. Water for washing. Compressed air; total consumption of 1500 l/ min. Nitrogen (on the packaging machine).

5 – Power supply, 220V 50 Hz; total consumption of 5 kw / h. Compressed air; total consumption of 1000 l / min.

The line consists of:

| Name | Work description | QTY | |

| 1 | Bag distribution machine | Distribution of the bags for the further transferring then into the bins | 5 |

| 2 | Screw conveyor |

Moving raw materials into the hopper - automatic feed |

5 |

| 3 | Raw hopper (5 m3) | Storage bins equipped with sensors | 5 |

| 4 | Screw conveyor |

Supply of raw materials to the weighing terminal |

5 |

| 5 | Raw feed control unit | Turning conveyors, display sensors for filling hoppers, switching hoppers |

1 |

| 6 | Weight termibal | Transferring between the hoppers, stop under them and lading cereals by weighing | 1 |

| 7 | Mixer | Mixing raw | 1 |

| 8 | Control device | Control over the batching complex, mixer, sifter | 1 |

| 9 |

Screw conveyor

|

Feeds the raw from mixer to sifter | 1 |

| 10 | Sifter | Sifts the raw | 1 |

| 11 |

Screw conveyor

|

Подает сырьё в экструдер | 1 |

| 12 | Extruder | Production of semi-finished product | 1 |

| 13 | Extruder control device | Control over the raw feeding, reverse of the main drive and rotation speed of the cutting device, heating temperature | 1 |

| 14 | Extraction | Removal, sucking the steam | 1 |

| 15 | Pneumatic conveyor | Moving of semi-finished product | 1 |

| 16 | Storage bin | Serves for storage of semi-finished product | 1 |

| 17 | Crasher-grinder | Grinds semi-finished product | 1 |

| 18 | Device for control of the crusher and pneumatic conveyor | Switching on the movement of transferring the product from the hopper to the crusher, grinding and transferring the product to the bin | 1 |

| 19 | Screw conveyor | Moves the crushed semi-fabricate to the storage bin | 1 |

| 20 | Stirage bin | Serves for collection of different types of product | 1 |

| 21 | Screw conveyor | Transferring dry additives by the screw | 4 |

| 22 | Tanks for dry additives | Storing additives before the further feed (vitamin mixture, fruit powders, dry milk) | 3 |

| 23 | Device pf control for mixing ingredients | Switching on power supply, indication of barrels for dry additives, feeding of dry additives, filling mixer with product, feeding to the automat |

1 |

| 24 | Batcher | Batcher for bulk ingredients | 1 |

| 25 | Mixer | Mixes grinded semi-fabricate with additives | 1 |

| 26 | Screw conveyor | Mixing with screw for the further distribution of the product | 1 |

| 27 | Filling machine | Product distribution | 1 |

| 28 | Ttransmitting unit | Moving packs from packing machine (film) into the machine for packing in cartoon | 1 |

| 29 | Automated packer into the cartoons | Cartoonpackingmachine | 1 |

| 30 | Horizontal conveyor | Moving packed products on the packing table for packing in bulk packages (boxes) | 1 |

| 31 | Packing table | Serves for easy packing of the finished products into the bulk package. | 1 |

| 32 | Horizontal conveyor | Transferring packed products to the store. | 1 |

| 33 | Compressor with receiver | Providing compressed air to the line elements. | 1 |

| 34 | Technical regulation documentation | 1 | |

The line is certified in Ukraine, EAEC and EU.