Production and packaging of the crisp air mouth-watering corn sticks.

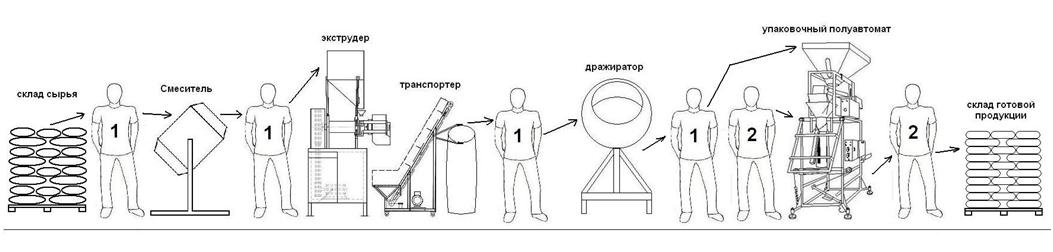

Work description of the line:

The operator 1 takes the cereals from the warehouse of raw materials and pours into the mixer to moisturize before extrusion. After 5-7 minutes, the operator 1 pours moistened cereals into the hopper of the extruder. Full extruder hopper (50 kg of cereals) is processed about 30 minutes. The semi-finished product comes out from the extruder –the corn sticks, which is fed into the bag with conveyor. When the bag is filled, the operator 1 changes the bag and pours the stick in to the pelletizer (2 kg per a cycle), sprinkle with oil, it is possible to make with the water spray for flowers or a garden sprayer and puts in a flavor (powdered sugar) manually. Pelleting process takes about 4 minutes, after which the operator 1 pours the finished product 1 from pelletizer and pours it into the hopper of semi-automatic packaging. Operator 2 packs the product on the packaging in semi-automat in packs of set weight and carries out group packing in plastic bags. Then the product, packed in shipping containers, is transferred to the store of the finished goods.

Photos line elements: