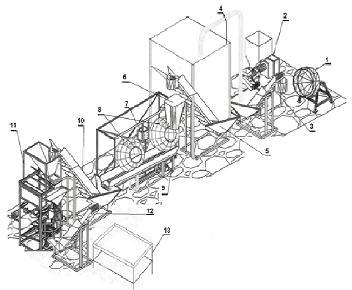

The line is designed for automatic continuous production of corn sticks.

How it works:

Raw materials (corn grits) is moistened in a mixer before extrusion. Further, the raw material is fed by the operator into the hopper of the extruder. At the exit the extruder we have a semi-finished product - corn sticks. The semi-finished product is fed into the storage bin automatically by pneumatic conveyor.The stick arrives from the hopper my means of vibrating natcher to the bucket conveyor, which moves the stick into the cone of the weighing device. When the required dose is loaded in cone, the strain gauge transducer sends a signal to stop the drive of vibrating batcher and supplying conveyor. Controlled dose (using weights device) is required to comply with the percentage of flavor additive to the stick.Retuning of measurement cone to the grinders is performed manually by the operator along the guide line. The semi-finished product is poured from the cone into the grinder, the puts the oil using oil-pumping station and a dry flavor additive. After the sticks comes out from the grinder we are able to obtain the finished product. The product is supplied on a horizontal conveyor by which it is fed into the hopper vibrating batcher The product gets into the bucket conveyor by vibrating batcher in order to supply the stick into the hopper of packing and filling machine. At the exit to the packaging and filling machines we have finished product packed in a plastic film product - corn sticks with flavoring additive. Pockets arrives from the packing machine to the outgoing conveyor which picks up the packages on the packing table, where they are packed in shipping containers.

The line consists of:

Line specifications: