The dairy workshop “Waiz -500” consists of the 1st module of full operational readiness. The workshop is equipped with all necessary equipment and communications for the full technological cycle of milk processing.

The workshop meets sanitary requirements, standards of fire and electrical safety, labor protection rules. Sanitization treatment of equipment and workshop facilities is carried out in accordance with the instructions of the Russian Institute of the dairy industry. Workshop equipment and milk pipelines are made of high quality stainless steel.

Workshop purpose

Acceptance, cleaning, processing of 500 kg of milk per day to produce the following products:

• Pasteurized milk (GOST R 52090-2003), packed in plastic bags.

Product calculation for one day (example)

Raw:milk (MJ 3.7%) - 500 kg.

Finished products:

• Pasteurized milk (MJ 3,7%) – 500kg.

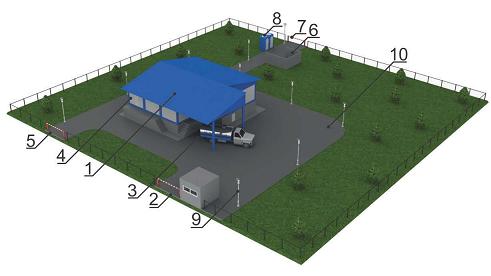

Design solutions of modular dairy workshop "Waiz-500" (example)

1. Modular dairy workshop "Waiz-500"

2. Access road for transport

3. Place of milk reception

4. Place of shipment of finished products

5. Transport exit way

6. Area for garbage bins

7. Access / exit for waste collection vehicle

8. Toilet

9. Supports Lighting

10. Sanitary scuttle

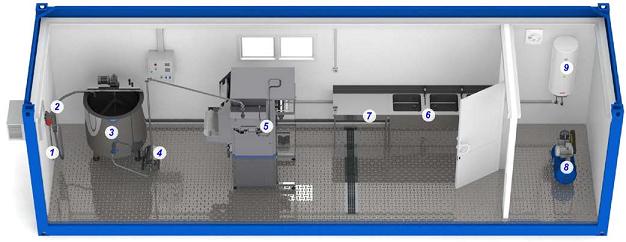

The layout and structure of the basic workshop equipment

1. flask milk pump 3000 l / h

2. milk filter, 1000 l / h

3. durable pasteurization bath, 250 liters of milk

4. milk pump 1000 l / h

5. automatic packaging of milk in the p / e packets to 20 bags / min

6. three-nest cleaner

7. technological table 900h600h800

8. compressor

9. water heater, 200 liters.

Technical specification of workshop

|

Parameter |

Unit of measurement |

Value |

| 1.Overall dimensions | mmхmmхmm | 9000х 2500х2790 |

| 2.Weight | kg | 4500 |

| 3.Power supply | ||

| rated power | kW | 32 |

| voltage | V | 380/220, ±5% |

| electric 5-wire network | L1,L2,L3,N,PЕ | |

| 4.Water supply | ||

| quality of supplied water | According to the State Sanitary Construction Rules for drinking water (SanPin) 2.1.4.1074-01 | |

| water consumption |

m3/day |

3 |

|

supplied water pressure |

atmospheres |

from2to 4 |

| Supplied water temperature | °С | No mere, than6 |

| 5.Sewerage | ||

|

Speed of removal sinks removal rate sinks |

m3/hour |

3,5 |

| 6.Climatic conditions of operation | ||

| Temperature of environment | °С | from–45to+50 |

| snow load |

kg/m2 |

400 |

Additional workshop equipment

1. Administrative premises

2. Domestic premises

3. Chemical Laboratory

4. The generator of ice water

5. The homogenizer

6. Video Surveillance System (CCTV)

7. Steam generator

8. Fire and burglar alarm

9. Refrigerators

10. Warehousing and auxiliary facilities

Benefits of purchasing «VAYZ -500»

Project development consists of:

• Vol. 1-Total explanatory note;

• Vol. 2–Master plan and transportation;

• Vol. 3– Technological solutions;

• Vol. 4–Design solutions;

• Vol. 5-Engineering equipment, networks and systems;

• Vol. 6–Environment protection.