Automatic line for  production of a wide range of confectionery products with filling and without filling (sponge cakes with fillings, Belgian waffles, butter biscuits, waffle products - crisp, crambles, mini-cakes filled and unfilled, classic cakes, muffins).

The line is a compact, fully automatic multi-functional complex, which consists of the following elements:

‚ąí dough dosing system

‚ąí system for dosing of filling (liquid, semi-liquid, solid - nuts, raisins (optional)

‚ąí automatic lubrication system

‚ąí baking system

‚ąí system of automatic seizure of finished products.

| Specifications |   |

|  Productivity, pcs. / hour | |

| ¬†¬†¬†‚Äď Biscuit cakes (series AM, AS, NG) | 8¬†064 ‚Äď 8¬†736 |

|

¬†¬†¬†‚Äď butter rings (d = 50 mm) |

4¬†704 ‚Äď 5¬†096 |

| ¬†¬†¬†‚Äď butter hearts (51—Ö56—Ö14 mm) | 8¬†064 ‚Äď 8¬†736 |

| ¬†¬†¬†‚Äď butter hearts (80—Ö86—Ö16 mm) | 4¬†704 ‚Äď 5¬†096 |

| ¬†¬†¬†‚Äď Belgian waffles(80—Ö42—Ö15 –ľ–ľ) | 5¬†376¬†‚Äst5¬†824 |

| ¬†¬†¬†‚Äď Belgian waffles (65—Ö65—Ö15 –ľ–ľ) | 4¬†032¬†‚Äst4¬†368 |

| ¬†¬†¬†‚Äď crips | 4¬†032¬†‚Äst4¬†368 |

| ¬†¬†¬†‚Äď crambles | 4¬†032¬†‚Äst4¬†368 |

|  Number of forms in the line, pcs | 26 |

|  Dimensions of the form set, mm | 440 х 140 х 50 |

|  Dimensions of baking area, mm | 410 х 90 |

| Installed capacity, kW | 41,0 |

| Power consumption, kW | Less, than 25,0 |

| Rated voltage, V | 380 / 50 –ď—Ü |

| Baking temperature, degrees –° | 170 ‚Äď 220 |

|  Consumption of compressed air, m3/hour | 21 |

|  Volume of the hopper for dough / filling, l | 30 / 30 |

|  Overall dimensions (L*W*H), m | 3,40х1,60х1,30 |

| Material of forms | Alluminium |

|  Weight of full set of forms, kg | 210 |

|  Furnace and the set of forms weight, kg | Not more, then 900 |

| Warranty, months | 12 |

The line includes a complete set of all forms.

Productivity kg / hour = pcs. / hour * Product weight (kg).

Extensive opportunities:

- Large production assortment:

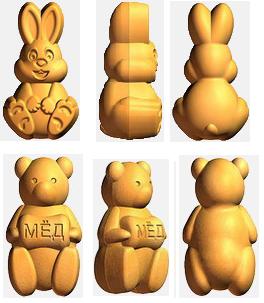

1. Sponge cakes in form the figures of any shape with filling and without it.

2. Butter (vanilla) cookies with filling and without it. For example, filled home mini heart or ring with uniformly distributed filling along the product - such products may only be produced in our furnace.

3. Viennese waffles (Belgian waffles) of biscuit dough.

4. Wafers (Crisp and crambles).

5. Mini-cakes with filling and without it.

6. Classic cakes with filling and without it.

7. Muffins with filling and without it.

- Dough and the filling does not drip on the form because the nozzles overlap after jigging dough.

- High-precision dosing group can jig the filling inside the dough by principle ‚Äúnozzle in dyuze‚ÄĚ (as in jigging machines). Due to it the filling is uniformly distributed throughout the product. It also allows to change arbitrarily the relationship between the dough and filling, at the same time without fear of breaking the product and exit the filling outside the product. In the output of the line, we guarantee the product with precise edges and weight.

- Dough and / or filling batcher hopper can be divided into groups. This makes it possible to produce, for example, sponge cakes assortment by dough (6 elements of biscuit dough color + 6 elements of chocolate color), as well as by the filling (6 elements with cream filling + 6 elements with chocolate filling).

Options of division the hoppers of the dough and / or the filling:

1. The total number of elements is divided into two equal groups.

2. Twelve elements are divided into three groups each of 4 elements.

-

The system of drain channels on the forms and within the line, as well as the diversion and ventilation system can effectively remove fats and evaporations into the special containers. This reduces in times the period of maintenance  concerning cleaning baking forms and cleaning the line itself.

-

The system of automatic pollination of top and bottom part of the form by the non-stick liquid allow to save in times the expensive imported lubricant (due to precise dosage of the sprayer) and to release completely the operator from unnecessary work.

-

Absence of the form jamming, lack of constantly breaking mechanical drives, all movements are based on pneumatic.

-

Control over the line operation is carried out by one person. The second person prepares dough and filling.

-

Production capacity:

- The line productivity is more, than of any Korean and Chinese machines by at least 50%. Due to the fact that the total number of cake elements in the line makes 312 pieces (by twelve elements on one form).

Electricity saving:- Tunnel principle of baking (heating form from the top and from the bottom inside the tunnel) can significantly save the energy. Insulation on the basis of ceramic fiber with a reflective foil. If necessary, you can quickly access to the forms in the tunnel by holding its top cap with the pneumatic lifting system, which is controlled by a joystick. Tunnel principle of construction line provides additional opportunities for assortment of baked products (classic cakes, muffins, mini cakes - all these products can be baked both with filling and without it).

Control system:- There are two principles that lied in the control system basis:

- Intuitive understandable interface based on the control rack touch - screen LCD 10’.

- Feed-back with operator by principle ‚Äď ‚Äúoperator‚Äôs assistant‚ÄĚ

- The control system allows the operator to be in the range of 10 meters from the line in case of emergency situations the system enables the operator to alert the appropriate sound and light signal with the output of the corresponding information message on the LCD screen of control rack.

- The LCD screen displays animated information on the work of all the nodes of the line.

- A list of emergence events that the control system responds:

1. Low level of dough or filling2. Failure in operation of any heater3. Failure in operation of the sensor4. Lack of compressed air supply5. Emergence stop of baked formsAssortment of forms:‚ÄĘ We first implemented the principle ‚Äď ‚Äúa set of elements on a form‚ÄĚ. I.e. shape we can place on each form precisely those elements that you need (from the catalog) and it is already included in the final cost of the line, or an additional set of forms.‚ÄĘ The range of forms in the catalog is expanding every month. Once a month we create 8 new products.‚ÄĘ We can make a set of interchangeable plates for our lines or any other lines (Japanese, Korean, or Chinese) on your sketches or designs of any complexity. We can make products with the company‚Äôs logo.Economy:‚ÄĘ The line takes minimum space for its performance. Convenient layout of key operating units.‚ÄĘ It is provided on the line an opportunity of receiving conveyor for the ¬†finished products.Ease of operation and maintenance:- Ease and quick installation of the line.

- Easy and thorough cleaning.

‚ÄĘ Easy setup of equipment mode.‚ÄĘ Easily transported to another place.‚ÄĘ Smooth movement of forms by the use of dampers on pneumatic cylinders.‚ÄĘ Easy to replace the working forms.Accessories‚ÄĘ Pneumatics from the world manufacturer Camozzi (Italy).‚ÄĘ Industrial fittings from the leader of this industry Elesa + Ganter (Italy - Germany).‚ÄĘ Burners from the world leader Lechler (Germany).‚ÄĘ Professional electronics from the company Delta (Taiwan).‚ÄĘ High-quality powder painting.‚ÄĘ All dosing group is made of food stainless steel. Baking forms are made of AK-7 (primary aluminum, the world's leading supplier - RUSAL).‚ÄĘ The factory quality of assembling.Minimal delivery time:- The maximum period of manufacture of any model line is 60 working days

Additional equipment:-

Cooling conveyor exhaust type for the finished product.