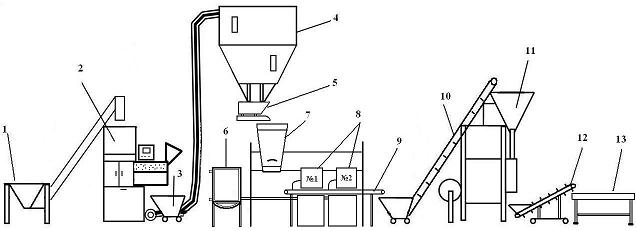

Automated line for production sweet, salty and caramelized popcorn, with capacity of up to 1tons / day.

The line consists of:

1. Screw conveyor, is designed to feed grains of popcorn into a hopper of popcorn machines -

2. Popcorn machine, makes popcorn from grains

3. Pneumatic conveyor, supply of popcorn by air to the damper hopper of the line

4. Digester, producing caramel

5. Weighing device dimensional cone, for dosing batches of popcorn flavors

6. Horizontal conveyor, to collect pop-corn out from caramelizer

7. Storage bin, for mating performance of all line elements

8. Vibration chute, uniform continuous feed

9. Caramelizers №1, №2, application of aroma- flavors additives on popcorn

10. Belt conveyor, for feeding pop-corn on the package machine

11. Packaging machine, for packaging popcorn, by 50, 100, 150 gr

12. Output conveyor, removal of packs of popcorn from the machine

13. Table for filling and packaging, for stacking packs of popcorn in a shipping container

Photo