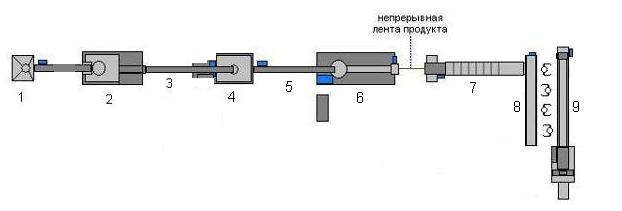

The line is intended for the production of loaves in automatic mode, semi-automatic packing.

Line of production capacity 140 kg/h

1. Screw feeding conveyor with receiving hopper;

2. Sifter;

3. Screw conveyor;

4. Mixer;

5. Screw conveyor;

6. Extruder;

7. Cutting and forming device;

8. Storing horizontal conveyor;

9. Horizontal packaging machine.

Brief technological description of the loaves production process

The raw in form of flour is discharged from the shipping container into a screw feed conveyor (1) by which it is loaded into a continuous sifter (2). Sifted flour is unloaded into the mixer (4)through the screw conveyor (3) .

The raw is fed into the storage bin of extruder (6) from the mixer with the screw conveyor (5). Twin-screw extrusion installation makes thermo-mechanical processing of initial raw, entering after the preparation phase. On exit from the extruder the matrix is set to a specific product.

Continuous feed of the product passes through the cutting and forming unit (7), where it is rolled and cut. During passing the belt along the device the fans cool and dry the belt of extrudant. On the exit the product is discharged on the conveyor belt.

The final stage of production - packaging. Ready-to-eat loaves are fed to a horizontal conveyor (8) where the packers shift them in stacks on the feed conveyor of the packaging machine (9).

The loaves stacked in strictly designated number. The product is then transferred to the packaging pulling rollers with wrapping film, where there is the welding of seams. Then packed loaves are unloaded on the output conveyor for packaging in shipping containers.

Power of line 133 kW.

Air consumption rate 200 l / min.

Water consumption up to 60 l / h.

Requirements space for equipment - 80 m2,

ceiling height - 4.5 m.

Attendants 9 people.

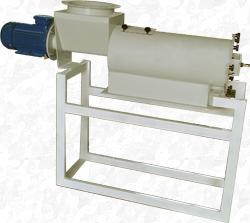

Photo equipment

Photos stacking loaves to feed conveyor of the packaging machine