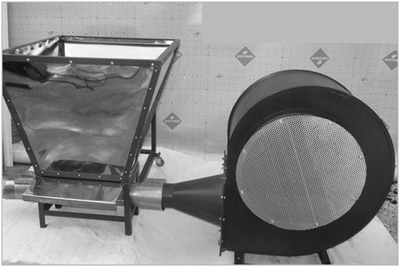

Pneumatic (air conveyor) is designed to move the light products, such as corn sticks on the large horizontal and vertical distances. The product flows into the hopper where it is directed into the piping system by the air flow.

Technical specifications:

| Power supply | |

| Supply voltage, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption kW / h | 0.5 |

| Dimensions and weight * | |

| Length (max) mm | 1 750 |

| Width (max) mm | 750 |

| Height (maximum) mm | 2 700 |

| Weight (less than), kg | 100 |

| Work features | |

| Lifting height of the product **, mm | 2 500 |

| Hopper capacity for the product, l | 60 |

| Speed of buckets movement, m / sec. | 3 |

| Adjustable parameters | |

| Vibration amplitude of the feeder,% | 0-100 |

| Functional hopper (tank) filling level ***, % | 10-90 |

* dimensions and weights are determined by the lifting height of the product.

** contains the standard lifting height. It is possible to manufacture the conveyor for the specified customer lifting height.

*** control for the filling level of the functional hopper (tank) is made by installing of the tank sensor into such hopper. Adjusting of the filling level is made by setting the required height of such tank sensor.

Horizontal conveyor is an optional equipment that is used for the movement of products between production facilities, workshops, lines, etc.