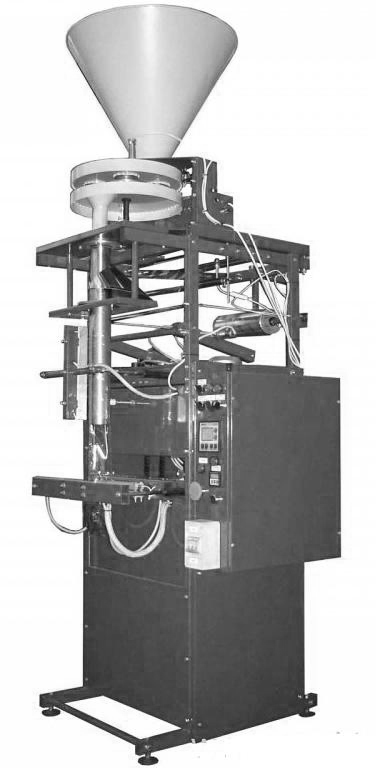

Filling and packaging machine is used for continuous process of packaging by volumetric dosing method of flowable, non-dust products and packaging into the polymer films.

The automatic packing machine includes automatic packaging device and volumetric batcher. In automatic mode it performs up to 35 packs / min.

Packaging machines is optimized equipment for packing products of good flowability and ability equally and quickly to fill empty spaces of the products (sugar, rice, seeds, salt and so on.). This model is not used for hard-flowable products (raisins, corn sticks and so on.) Due to existence of the volumetric batcher the machine has limitations for replacement of packed products. The machine also requires flour location. There are some limitations on the width of the used film and the package height. These limitations are included in specification. It is also possible to produce large size machine: the minimal film width – up to 500 mm, package height – up to 400 mm.

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 1.5 |

| Power of pneumatic drives | |

| Airpressureinline (average), atm. | 6 |

| Airconsumptionataveragepressure, l./min. | 100 |

| Overalldimensionsandweight | |

| Length (max), mm | 1500 |

| width (max), mm | 1500 |

| height (max), mm | 2800 |

| weight (max), kg | 350 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 380 |

| External diameter of the roll (max), mm | 300 |

| Working characteristics | |

| Volume of the hopper for raw material, l | 60 |

| Dosing limits (nominal volume of the «body»*), sm3 | 50-1200 |

| Dosage error (allowable), % | 2 |

| Dosingspeed (max), doses/min: * | 35 |

| Welding (soldering), packingtime (includingcooling), sec. | 1-2 |

| Heating of welding unit (welding method) | Continuous |

| Length of packing (max), mm | 300 |

| Packing width (max), mm | 200 |

| Adjustable parameters | |

| Dose volume (range), sm3 | 30 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* «body» isreferredtoasthemetalcapacity, byfillingtheinternalspaceofwhichthe product dosing is carried out.

** Packing equipment performance depends on the type of packaged product, its flowability, density, moisture content, dose size and properties of packaging material.

To insure the functionality of pneumatic drives of this packing and filling equipment it is necessary to have compressor (is supplied separately).