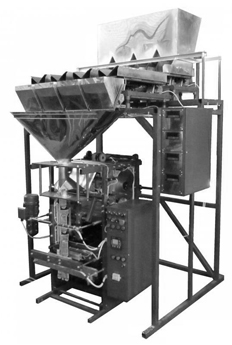

Automatic packaging machine is used for continuous process of packaging by weight dosing method of various flowability (hard-flowable), non-dust products and packaging into the polymer films.

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 2.5 |

| Overall dimensions and weight | |

| Length (max), mm | 2000 |

| width (max), mm | 1500 |

| height (max), mm | 2800 |

| weight (max), kg | 400 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 380 |

| External diameter of the roll (max), mm | 300 |

| Working characteristics | |

| Volume of the hopper for raw material, l | - |

| (hopper with 1 spout) | 60 |

| (hopper with 2 spouts) | 120 |

| (hopperwith 3 spouts) | 180 |

| (hopper with 4 spouts) | 240 |

| Dosing limits (dose weight), g | 20-2000 |

| Dosage error (allowable), % | 2 |

| Dosingspeed (max), doses/min: * | - |

| (batcher with 1 “stream” **) | 10 |

| (batcher with 2 “streams” **) | 20 |

| (batcher with 3 “streams” **) | 30 |

| (batcher with 4 “streams” **) | 40 |

| Welding (soldering), packingtime (includingcooling), sec. | 1-2 |

| Heating of welding unit (welding method) | continuous |

| Length of packing (max), mm | 300 |

| Packing width (max), mm | 200 |

| Adjustable parameters | |

| Dose volume (range), sm3 | 20-2000 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* thepackingmachineperformancedependsonthetypeofpackagedproduct, itsflowability, density, moisturecontent, dosesizeandpropertiesofpackagingmaterial.

** the “stream” means units and devices insuring forming of separate stream of the packed product from the batcher-hopper, its division by doses and issuing these doses in the certain subsequence. The “stream” consists of: the hopper spout with hopper, vibrating chute disposed below a spout, the weighing beaker in which the vibrating chute feed the product, and a controller unit controlling the operation of the vibrating chute and weighing beaker.