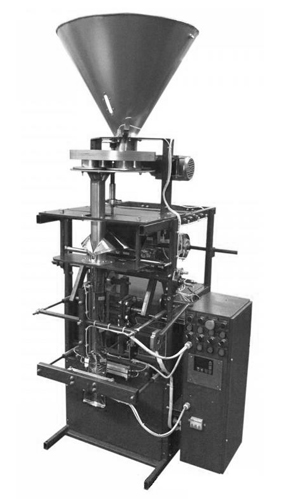

Filling and packaging machine is used for continuous process of packaging by volumetric dosing method of flowable, non-dust products and packaging into the polymer films.

The automatic packing machine includes mechanical packaging device and volumetric batcher. In automatic mode it performs up to 35 packs / min.

Packaging machines is optimized equipment for packing products of goodflowability and ability equally and quickly to fill empty spaces of the products (seeds, cereals, sugar, rice, grain, seeds, salt, tea, coffee beans). This model is not used for hard-flowable products (corn sticks, flour, raisins) and also has limitations for replacement of packed peoducts. The difference of this equipment is the usage of mechanical packaging machine. A special feature is the absence of pneumatic drivers, which excludes the use of the compressor. The advantages of packaging machines is small dimensions and silent work .

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 2.5 |

| Overall dimensions and weight | |

| Length (max), mm | 1100 |

| width (max), mm | 950 |

| height (max), mm | 2200 |

| weight (max), kg | 300 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 380 |

| External diameter of the roll (max), mm | 300 |

| Working characteristics | |

| Volume of the hopper for raw material, l | 60 |

| Dosing limits (nominal volume of the «body»*), sm3 | 50-1200 |

| Dosage error (allowable), % | 2 |

| Dosingspeed (max), doses/min: * | 35 |

| Welding (soldering), packingtime (includingcooling), sec. | 1-2 |

| Heating of welding unit (welding method) | Continuous |

| Length of packing (max), mm | 300 |

| Packing width (max), mm | 200 |

| Adjustable parameters | |

| Dose volume (range), sm3 | 30 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* "body" is referred to the metal container, with filling the interior space of which the dosing of the product is performed.

** thepackingmachineperformancedependsonthetypeofpackagedproduct, itsflowability, density, moisturecontent, dosesizeandpropertiesofpackagingmaterial.