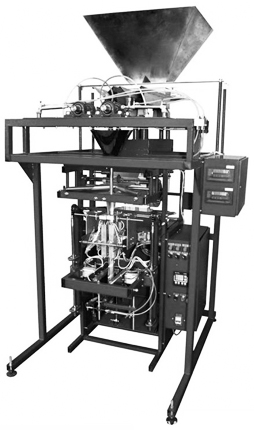

Filling and packaging machine is equipped with a weight batcher and is designed for automatic filling in single-usage package type sachet of non-dusting product withgood flowability, such as sugar, salts, soluble powders, soluble coffee, and others. It is not suitable for packing dusty (dust-raising) products (sugar powder, pepper).

It works in automatic mode, performance is up to 35 packages / min. The design and dosing device allows to change the size of the dose of the packed product and provides accurate dosage.

This packaging machine forms a rectangular or square package with four seams (“Sachet”, sachet-package).

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 1.5 |

| Power of pneumatic drives | |

| Air pressure in line (average), atm. | 6 |

| Airconsumptionattheaveragepressure, l./min. | 150 |

| Overall dimensions and weight | |

| Length (max), mm | 1000 |

| width (max), mm | 1300 |

| height (max), mm | 2200 |

| weight (max), kg | 250 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 100-360 |

| External diameter of the roll (max), mm | 300 |

| Working characteristics | |

| Volume for the hopper for packaged product, l | - |

| (hopper with 1 spout) | 60 |

| (hopper with 2 spouts) | 120 |

| Dosing limits (dose weight), g | 1-100 |

| Dosage error (allowable), % | 1 |

| Dosingspeed (max), doses/min: * | - |

| (batcher with 1 “stream” **) | 15 |

| (batcher with 2 “streams”**) | 35 |

| Welding (soldering), packingtime (includingcooling), sec. | 1-2 |

| Heating of welding unit (welding method) | continuous |

| Length of packing (max), mm | 180 |

| Packing width (max), mm | 180 |

| Adjustable parameters | |

| Dose volume (range), sm3 | 10-250 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* the packing machine performance depends on the type of packaged product, its flowability, density, moisture content, dose size and properties of packaging material..

** the “stream” meansunitsanddevicesinsuringformingofseparatestreamofthepackedproductfrom the batcher-hopper, its division by doses and issuing these doses in the certain subsequence. The “stream” consistsof: thehopperspoutwithhopper, vibrating chute disposed below a spout, the weighing beaker in which the vibrating chute feed the product, and a controller unit controlling the operation of the vibrating chute and weighing beaker.

To insure the functionality of pneumatic drives of this packing and filling equipment it is necessary to have compressor (is supplied separately).