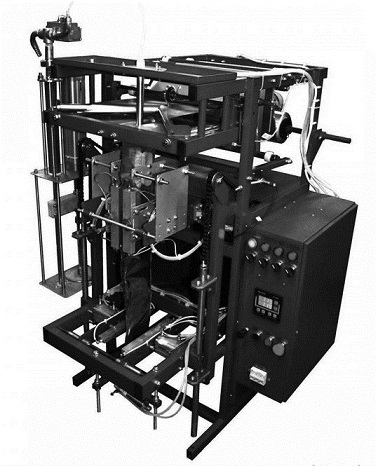

Packaging machines for the organization of continuous cycle of filling by volumetrically mode dispensing liquids and paste fluids and packing them into the portion dose packages such as “sachets” (sachet-pack).

It consists of a packaging machine and the volumetric liquid batcher. It operates automatically and provides performance of up to 35 packs per minute.

Packaging machines is best for batch filling of liquids (water, juice, perfumery products, medical drugs) or pasty fluid substances (ketchup, mayonnaise, liquid soap). Applying this model provides a convenient package in the form of rectangular or square bag with three or four seams (sachet bag, “sachet”). It should be noted, that due to the application of volumetric batcher the model is not universal, and has limitations of the issued dose associated with sizes of measure cylinder.

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 1.5 |

| Power of pneumatic drives | |

| Air pressure in line (average), atm. | 6 |

| Airconsumptionattheaveragepressure, l./min. | 150 |

| Overall dimensions and weight | |

| Length (max), mm | 1000 |

| width (max), mm | 1100 |

| height (max), mm | 1600 |

| weight (max), kg | 250 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 100-360 |

| External diameter of the roll (max), mm | 300 |

| Workingcharacteristics | |

| Volume for the hopper for packaged product, l | произвольно |

| Dosing limits (dose weight), g | 10-250 |

| Dosage error (allowable), % | 1 |

| Absorbingspeedthroughtheabsorbingnozzle, sec.** | 0-3 |

| Issuing speed through the nozzle of issue, sec ** | 0-3 |

| Performance (max), packages/min: ** | 35 |

| Время сварки (пайки) упаковки, сек | 1-2 |

| Heating of welding unit (welding method) | постоянный |

| Length of pack (max), mm | 180 |

| Width od pack (max), mm | 180 |

| Adjustable parameters | |

| Dose volume (range), sm3 | 10-250 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* Equipment is able to inflow the dosed liquid (matter) form any tank by putting in it the absorbing nozzle, in connection with what the volume of such tank is not limited and is defined up to operator.

** Speed of absorbing through the absorbing nozzle and issue through the issuing nozzle depends of fluidability and density of the dosed substance (liquid).

To insure the functionality of pneumatic drives of this packing and filling equipment it is necessary to have compressor (is supplied separately).