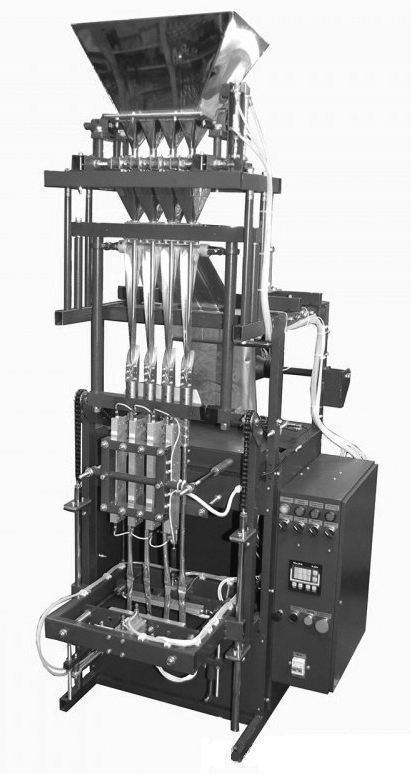

Packaging machines for the organization of continuous cycle of filling by volumetrically mode of dosing of well-bulked non-dust fined products and packing them in small doses into the bulk packing suck as “stick” (stick-pack).

It consists of a packaging machine and the volumetric pendulum batcher. It operates automatically and provides performance of up to 120 packs per minute.

Packaging machines is best for batch filling of products with good flowability and fine fraction, and the ability to fill quickly the empty space, such as salt, sugar, tea, pepper and grinded coffee. The application of this model allows to get comfortable pack in form of tube with 3 seams (stick-pack “stick”) used in the majority of cafes, restaurants and other catering establishments. It should be noted, that due to the application of the volumetric batcher this model is not universal, and is limited to changing of purchased product.

Specifications:

| Power supply | |

| Voltage supply, V | 380 |

| Supply current frequency, Hz | 50 |

| Power consumption, kW/h | 1,5 |

| Power of pneumatic drives | |

| Air pressure in line (average), atm. | 6 |

| Airconsumptionattheaveragepressure, l./min. | 100 |

| Overall dimensions and weight | |

| Length (max), mm | 1 000 |

| width (max), mm | 1 100 |

| height (max), mm | 2 900 |

| weight (max), kg | 300 |

| Sizes and thickness of packing material | |

| Thickness of packing material (allowable), microns | 20-60 |

| Width of the roll (max), mm | 200 |

| External diameter of the roll (max), mm | 300 |

| Working characteristics | |

| Volume for the hopper for packaged product, l | 70 |

| Dosinglimits (nominal volume of the space*), m3 | 2-20 |

| Dosage error (allowable), % | 2 |

| Dosingspeed (max), doses/min: * | - |

| (batcher with 1 «stream» ***) | 30 |

| (batcher with 2 «streams» ***) | 60 |

| (batcher with 3 «streams» ***) | 90 |

| (batcher with 4 «streams» ***) | 120 |

| Welding (soldering), packingtime (includingcooling), sec. | 1-2 |

| Heating of welding unit (welding method) | continuous |

| Length of packing (max), mm | 300 |

| Packing width (max), mm | 20 |

| Adjustable parameters | |

| Dose volume (range), sm3**** | 2-20 |

| Heating temperature of the welding unit (range), °С | 80-250 |

* Theemptyspaceismetallictank, byfillinginternalspaceofwhichthe product is dosed.

** The productivity of the filling and packing machine depends on the type of packaged product, its flowability, density, moisture content, dose size and properties of packaging material.

*** the “stream” means units and devices insuring forming of separate stream of the packed product from the batcher-hopper, its division by doses and issuing these doses in the certain subsequence. The “stream” consists of: the hopper spout with hopper, vibrating chute disposed below a spout, the weighing beaker in which the vibrating chute feed the product, and a controller unit controlling the operation of the vibrating chute and weighing beaker.

**** changing the dose size is made by replacement of the dosing blades.

To insure the functionality of pneumatic drives of this packing and filling equipment it is necessary to have compressor (is supplied separately).